Busway Schneider

Introduction

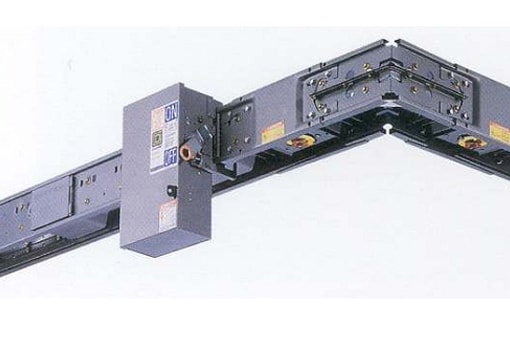

The busbar trunking system (from 800A), both feeder and plug-in, shall be sandwich construction. All busbar trunking products and fittings (straight length, elbow, tees, flanged ends, cable tap box and circuit breaker, etc.) shall be in accordance with IEC 60439:2005 or UL857 and from the same manufacturer as the busbar trunking system. The degree of protection of the busbar trunking system should be IP54 in accordance to IEC 60529.

Rated operation voltage of the busbar trunking is 1000V. 3 Phase, 4 Wire with 50% capacity continual integral/internal earth busbar. The neutral conductor should have the same cross-sectional area as the phase conductor (3P 4W 100%N + 50%E). The earth busbar must be one continuous piece without bolting on housing.

Application

Busway is used to transmit power instead of conventional power cable.

1. Housing

The busbar trunking housing shall be constructed of code gauge steel and aluminum to reduce hysteresis and eddy current loses and shall be provided with a suitable protective finish of ANSI 49 grey epoxy paint.

The busbar trunking housing shall be totally enclosed non-ventilated for protection against mechanical damage and dust accumulation. And it shall pass at least 500 hours salt spray test to ensure the anticorrosion ability.

The totally enclosed housing shall be manufactured by the busbar trunking manufacturer. Modifications of busbar trunking to make it totally enclosed by other than the busbar trunking manufacturer voids the manufacturer’s warranty. Busbar trunking so modified is unacceptable without the written consent of the manufacturer.

2. Busbars

Busbars shall be of hard drawn sliver-plated high conductivity copper of 99.9% purity or aluminum with bimetal cladding utilized Molecular Fusion technology

There shall be no bolts passing through the busbars of the busway

3. Insulation

Each busbar shall be insulated with Class B (130 ℃ DuPont Mylar) or Class F rated (155℃ DuPont Melinex) polyester film. Epoxy insulation is not allowed.

The temperature rise at any point of the busbar trunking enclosure shall not exceed 55 degree Centigrade rise above ambient temperature when operation at rated current.

4. Support of busbar Trunking

Hanger spacing shall be noted on layout drawings and shall not exceed manufacturer’s recommendations.

Indoor feeder and plug-in busbar trunking shall be approved for hanger spacing of up to 3 meters for horizontally mounted run and 4.88 meters for vertically mounted runs. Outdoor feeder busbar trunking shall be approved for spacing of up to 1.5 meters for horizontally or vertically mounted runs.

| Manufacturer | Schneider, Siemens |

| Standard | IEC 60439-2 |

| Country of Origin | China |

| Rated insulated voltage | 1000V |

| Rated current | Xem bản vẽ |

| Ingress of Protection (IP) | IP54 |

| Structure of Busway | 3 phase 4 bar: 3P+100%N+50%E |

| Integrated shell | |

| Type of Busway | Sandwich |

| Earthing | TNS |

| Conductor/ busbar type | Aluminum (Copper contact) |

| Material at joint (joint connections & tap off ) | Silver-plated Bi-metal cladding |

| Temperature rise at any point of the busbar enclosure | < 550C |

| Type of insulation | Polyester Dupont Mylar (Class B) |

| Class of insulation | B (1300C) |

| Safety mark on all the product (assurance full product safety testing, factory inspection & surveillance under independent authority) | KEMA-KEUR |

| Housing | |

| Housing material | Gauge steel & Aluminum |

| Housing finishing | Epoxy polyester powder coated (ANSI 49) |

Flexibility (can re-use, easy to develop more loading capacity or remove …)

Meet IEC61439-6 standard

Improve the quality of installation (simple in construction work, does not require high-skill in installation) and reduce maintenance time.

Improve reliability, safety and simplicity in the design construction … ..

High resistant to short circuit current

Low pressure drop

Good radiator & durability (protective shell made of metal)

Variety configure of Busduct is easy to choose

Integration with compact dimensions

RELATED PRODUCTS

Main Switchboadrds

Introduce:The switchboard distributes the total input MSB for the entire low-voltage electrical system of a building,Application:Installed in the general electrical engineering room of industrial and civil works

Read more

Transformer

Introduction:Great progress has been made in the development and improvement of distribution transformers over the last decades.The application of high quality insulation material and suitable selection of the coil structure for high stress have contribute to the development of LS CAST RESIN Transformers. The LSCAST RESIN Transformer has succeeded in combining the advantage of oil-filled and conventional dry type transformers, which are fabricated with anepoxy resin. The windings are completely embedded under vacuum conditions.This casting method makes it possible to assure void-free epoxy penetration of both the inner layer and turn to turn insulation.ApplicationLS CAST RESIN Transformers canbe used in various fields.Here are just a few possibleapplications.● Indoor and outdoor unit substations● Off-shore flatforms● Commercial buildings● Hospitals● Shopping centers● Water supplies● Traction systems● SCR Power supplies

Read more

Cable tray - Cable ladder

Introduction:Cable tray, cable ladder and supporting system is the main load bearing structure of electric cable system. These materials often being the last-order of electric materials in each project, thus the short delivery time is one of the key factors.Hawee is one of the pioneers in applying new modern material on producing cable tray, cable ladder and supporting system with the aim of shortening the delivery time to site.Application:Cable tray, cable ladder system is applied in all M&E system.

Read moreRelated Posts

HAWEE P&T AND NKE SIGNED A MEMORANDUM OF COOPERATION

On January 10, 2025 in Hanoi - Hawee P&T and Nippon Kouatsu Electric Co., Ltd. (NKE) officially signed a Memorandum of Understanding (MOU), marking an important step forward in the strategic cooperation relationship between the two businesses.

Hawee P&T Successfully Energized BlokSet Cabinet System of Ho Guom Theater

On the morning of June 23, 2023, Ho Guom Theater officially and successfully energized the BlokSeT, MDB, DB low-voltage cabinets... supplied by Hawee P&T.

BlokSet cabinets continue to be installed in phase II of Vinh Phuc General Hospital

Production and Trading Company (Hawee P&T) has just signed a contract to supply Blokset cabinets in phase 2 of the project of Technical houses and ancillary works - Vinh Phuc General Hospital